With Dunstone, Learning How to Use Heat Shrink Tape is Simple

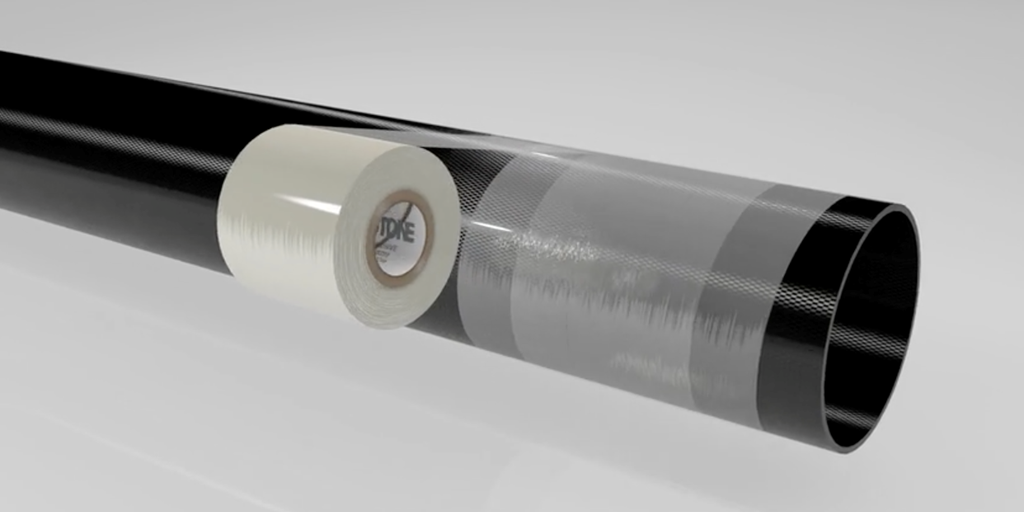

Heat shrink tape is the best way to appropriately compress composite materials, prepregs, and wet layups to create products that perform well immediately and long after the curing process. Properly applied, our Hi-Shrink Tape products help production teams in a variety of industries and markets achieve numerous goals through a single solution:

- Elimination of voids in the resin or between layers

- Eliminate foreign object debris (FOD)

- Remove outgassing volatiles or water vapor from curing resins

- Overall improved lamination of the composite material

- A superior surface finish (with or without marks from the tape)

- Higher mechanical strength from the cured composite

It’s important, however, to use specific practices when applying Hi-Shrink Tape to a prepreg or wet layup prior to cure. Doing so ensures that the shrink tape will produce the results you’re looking for — and that your customers demand in their applications.

If you’re looking to learn how to use heat shrink tape yourself or to help production team members refine their skills for more consistent output, follow the recommendations below. If you have any questions about how to use your Hi-Shrink Tape products, please feel free to reach out to us. We’ll be happy to help.

Best Practices for Using Shrink Tape

- Find the Right Tape for Your Application — The first step is to naturally identify the right type of Hi-Shrink Tape for your application. Basic applications won’t need shrink tape with significantly high compressive force or shrink percentages, whereas others might. If your curing cycle is extremely high-temperature, you’ll want to make sure you’re using an appropriately engineered shrink tape that begins to shrink at the right time. You may also need shrink tape with a release coating applied so that it can be easily removed. If your resin system and curing process produce gasses, a perforated shrink tape is not required but can assist with the removal of volatiles from the cured composite surface.

- Experiment with Tension — Taping tension is how tightly you wrap Hi-Shrink tape around your product. While taping tension can be somewhat forgiving, it’s important to experiment to find the right taping tension for your application. Typically, most people who are hand-wrapping shrink tape use between five and eight pounds of force. Feel free to use this handy calculator to determine tension and other factors.

- Be Consistent — Whether you’re applying a low amount of force (in pounds per square inch) or a much higher force amount, it’s absolutely critical to be consistent with your tension and overlap. For the latter, you’ll need to experiment here as well — some applications only need 25% overlap, but others can benefit from higher overlap at 50% or 75%. The overlap amount you choose will result in lesser or greater compaction force. A pro tip on how to use heat shrink tape is simply to keep it snug against the part as you apply it.

- Know Whether You Need a Release Coating — Depending on your resin system, you may need a release-coated Hi-Shrink Tape that allows the tape to be easily removed from the part post-cure (as opposed to grinding it off or leaving it on). We manufacture a variety of release-coated tapes (indicated by an ‘R’ after the product number — e.g. 220R). Pro tip: If you’re unsure which side of your tape is release-coated, simply take a Sharpie and mark it. If the mark ink beads up, that’s the release-coated side.

- Properly Secure the Tape — Because our Hi-Shrink Tapes don’t use an adhesive on either side, the tape must be secured to the part prior to curing. Fortunately, this is easy: simply secure the starting end of the tape with a piece of regular adhesive tape, or overwrap the tape around the starting end before proceeding laterally down the part. The same options can be used once you reach the end of the part.

Learn more about taping tension and other hand-wrapping considerations here.

Considering Automated Solutions for Your Application?

If hand-wrapping isn’t an option in your environment and an automated system for wrapping shrink tape is preferred, we will be happy to provide you with recommendations. We have worked with several manufacturers that can either develop an add-on wrapping system for existing equipment or design and build a system from the ground up.

Get More Answers to Your Questions

If you have additional questions about how to use heat shrink tape, our team is happy to help. Simply reach out and let us know what we can do for you. And remember that we offer custom solutions as well to ensure your application is a success.