Hi-Shrink polyester shrink tape is critical to the function and efficiency of many industries, including the automotive, oil and gas, marine, composites, and sporting goods industries. These solutions provide various advantages to each of these industries through their many beneficial properties. In this blog, we’ll review the features of Hi-Shrink polyester shrink tape, its uses, and how to properly apply these materials for efficient function.

Beneficial Features of Hi-Shrink Polyester Shrink Tape

Hi-Shrink polyester tape provides many benefits to various applications, including:

- Removing voids in the resin and between layers of resin

- The removal of foreign object debris

- Improved lamination of products

- High-quality surface finishes

- Improved mechanical strength in your cured part

- Minimization of the height of cello lines on cured parts

There are different types of Hi-Shrink polyester tape on the market, each of which offer these benefits along with others. Some of these tapes are able to function at very high temperatures, have release coatings on one or both sides, and offer a wide range of shrink percentages based on your needs.

Uses of Hi-Shrink Polyester Tape

Since different Hi-Shrink polyester heat shrink tapes have different properties, their applications may differ. Dunstone offers a wide range of Hi-Shrink tape solutions, and we’ve outlined their uses below.

100 Series

This polyester shrink tape is 0.001” thick and can be used for cure temperatures up to 165ºC. It applies low to moderate shrink force — though still higher than other options on the market — and is therefore ideal for use in thin-walled composite parts. Some common uses of our 100 Series Hi-Shrink tape include consolidating flexible ductwork, silicone, and rubber hoses during cure and vulcanization.

140 Series

Our 140 Series is 0.0014” thick and is also suitable for cure temperatures of up to 165ºC. With its low to moderate shrink force, it’s used to consolidate composite tubes, flexible ductwork, and silicone hoses.

200 Series

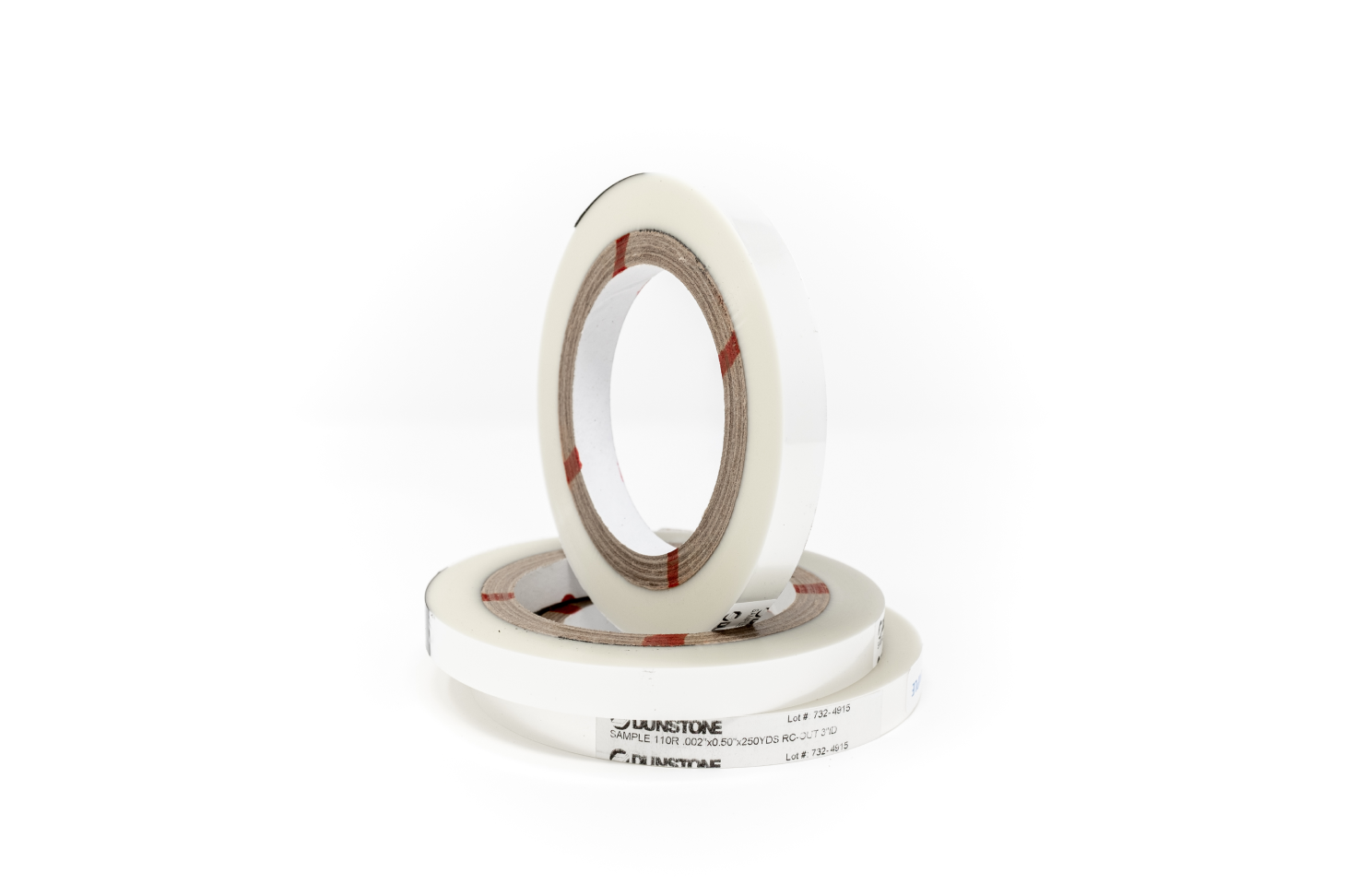

This Hi-Shrink tape is 0.002” thick and can withstand cure temperatures up to 165ºC. It provides low to moderate shrink forces and is commonly used to consolidate composite tubes, flexible ductwork, and silicone hoses, as well as other thin-walled composite applications. It’s the “Swiss Army knife” of shrink tapes and comes in a variety of formats, such as release coated on one or two sides, with or without perforations, and more.

300 Series

The 300 Series from Dunstone is a 0.003” thick polyester tape that withstands curing temperatures up to 165ºC and has a low to moderate shrink force. It’s commonly used on thicker-walled composites, including composite tubes, flexible ductwork, and silicone hoses.

500 Series

This thicker Hi-Shrink tape is 0.005” thick and can withstand cure temperatures up to 165ºC and has a moderate to high shrink force. This series is commonly used for thicker-walled composites and can consolidate large composite tubes, containment rings, and parts requiring high compressive forces.

Proper Application of Hi-Shrink Polyester Shrink Tape

First, you will need to start by understanding the needs of your application and finding the right tape for you. Once you’ve determined the right tape for your product, it’s time to start experimenting to find the right tension and overlapping percentage for your project.

The taping tension of Hi-Shrink polyester tape is how tightly you wrap the shrink tape around your product. The best way to determine this is through experimentation so you know exactly what tension works best for your product. If you want some additional information about how to determine tension, check out our calculator.

Overlapping will impact the compaction force of your Hi-Shrink tape. This is measured in percentages. The higher the percentage of overlap, the higher compaction force. These percentages usually fall between 25% and 75%.

When it comes to wrapping your product, it’s important to properly secure your Hi-Shrink tape. To do this, you can start the end of the tape with a regular adhesive tape or overwrap the tape around the starting end before proceeding laterally down the part. To learn more about the wrapping process, check out our video that walks you through the entire process.

Need Hi-Shrink Polyester Shrink Tape? Turn to Dunstone

At Dunstone, we manufacture various Hi-Shrink tape and tubing for a wide range of industries and products. We understand that our customers need their Hi-Shrink solution to function exactly as they need them to, which is why we offer custom converting solutions and shrink tape and tubing with different properties.

Contact our team today to see what we can do for you.