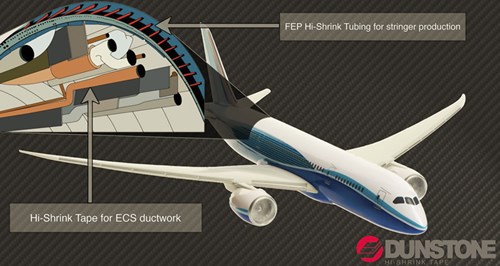

Dunstone Resolves Issues with Aerospace Composite Fuselage Stringe

Industry

Aerospace Composites

Application

Release coating of silicone bladders with heat shrink tubing, replacing hand wrapping process

Problem

Often times, composite fuselage skins for aerospace structures use composite stringers to stiffen the composite skin. Many times these composite skins are co-cured at the same time as the composite stringers. Composite stringers with trapezoidal or omega shaped cross section, typically 20’-40’ in length, require an inflatable silicone bladder on the inner mold line to provide internal compaction during cure. It is necessary to cover the bladders with a release film prior to application of carbon fiber pre-preg, the release film allowing for removal of the tool after the autoclave cure cycle. The silicone bladders were wrapped by hand with release film, and taped into place using Teflon tape. This can be a costly and time consuming process required for each fuselage section, and it often resulted in difficulty removing the hand wrapped release film after part cure due to the adhesive tape becoming stuck on the ID of the cured stringer. Material that remains on the inside of the cured part has to be completely removed before the part can be cleared for subsequent processing. Re-work and labor to remove the trapped film is costly and needs to be eliminated.

Dunstone Solution

Implementation

Dunstone Hi-Shrink FEP Tubing used in the bladder preparation process allows the customer to prepare more parts in less time in order to incorporate them into the larger fuselage section prior to autoclave cycle. Our FEP tubing shrinks quickly, and without wrinkles, requiring less heat to fully shrink when compared to other heat shrink release film tubes. Dunstone Hi-Shrink FEP Tubing has uniform thickness which give it uniform shrink percentage throughout.