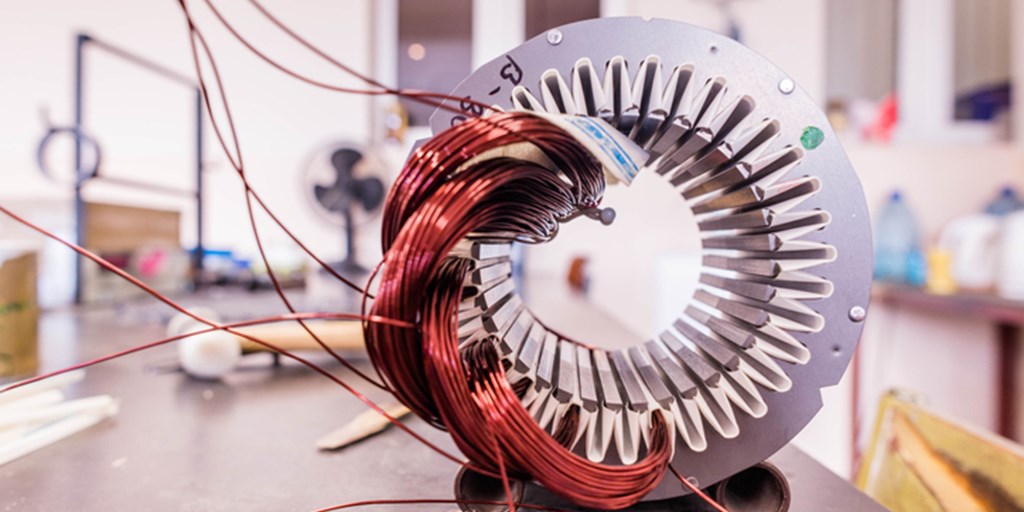

Multiple industries rely on electrical coils and other components for their services and products. But the key to success is ensuring those parts are properly produced.

Electrical heat shrink tapes are essential to that outcome. Examples of products requiring this kind of shrink tape include high voltage (HV) coils, resin-rich coils, DC field poles, pre-consolidated coils, wiring systems, and other products requiring a sacrifice film, compression, or dielectric insulation.

Whatever the need, Hi-Shrink Tape from Dunstone is one of the leading solutions for companies looking to achieve excellence in the performance and longevity of their manufacturing processes.

Why Hi-Shrink Tape?

Non-shrink films like cellophane, woven nylon, and polypropylene have to be wrapped at high tension and in multiple layers in order for the material to provide the necessary compaction. The problem is that these materials relax as the curing temperature rises — right when the resin begins to drop in viscosity and flow. The results are less than ideal.

That’s why Dunstone developed our Hi-Shrink Tape products. These tapes begin shrinking at 70ºC / 158ºF and apply compressive force as the temperature rises along a tailored curve. The result is a more even compression process that eliminates foreign object debris (FOD), air voids, and a resin-rich surface finish. Additionally, because Hi-Shrink Tape gets the job done the first time and with less material, costs associated with this part of the production process are reduced.

Learn how to find the best heat shrink tape for your application.

Examples of Electrical Heat Shrink Tapes from Our Portfolio of Products

140 Series

The 140 Series of electrical heat shrink tape was designed for applications in the high voltage coil industry because it provides the right amount of tensile strength while remaining cost effective. As part of our complete 100 Series, the 140 line is only 0.0014” (0.0035mm) thick — making it one of our thinnest Hi-Shrink Tapes. Its shrink percentage can be adjusted based on the application (though it’s ideal for thin-walled composite parts) and is available with a single- or double-sided release coating for instances when the tape needs to be removed from the part after the curing process is finished.

Learn more about our 140 Series Hi-Shrink Tape.

200 Series

The 200 Series Hi-Shrink Tapes are our most common shrink tape, working perfectly for a wide variety of applications — electrical and otherwise. Specifically, the 220R line has been used in electrical applications that include power generation. In one example, an OEM wanted to use our Hi-Shrink Tape to prevent fatigue and wear of end-windings on HV coils. Not only did 220R provide maximum consolidation of the insulation materials being used but it also worked well in the sharp coil radii where it can be challenging to properly consolidate layers. The 220R line is only 0.002” (0.050mm) thick, and just like the 140 Series is available with a 1- or 2-sided release coating — allowing the resulting surface finish to be free from defects and eliminating the need to grind the tape off.

Learn more about our 200 Series Hi-Shrink Tape.

X Series (208X)

Our X Series tape was designed for applications where the usage temperature is much higher (up to 200ºC / 392ºF for electrical usage and even higher for mechanical usage) and in which the curing temperature is higher than other shrink tapes can handle. A modified polyimide material, our X Series Hi-Shrink Tape begins to shrink at 70ºC / 158ºF but will reach its maximum shrink percentage at 350ºC / 662ºF. It is most often used to consolidate HV coils and is typically not removed from the part. Like our 200 Series, it is only 0.002” (0.050mm) thick, providing the compressive force needed in a single material while providing additional dielectric and mechanical properties as well.

Learn more about our X Series Hi-Shrink Tape.

500 Series

Last but not least is our 500 Series of Hi-Shrink Tapes. This line of products is our thickest at 0.005” (0.125mm) and also provides the highest amount of shrink force of our entire Hi-Shrink Tape product line at 21.64 pounds of force at 150ºC / 302ºF. Because of this immense pressure that it can exert on a part, it is most often used for consolidating rubber hoses, flexible ductwork, and silicone hoses, but it does have utility in electrical applications such as HV coils. Like some of the products mentioned here, it’s available with a 1- or 2-sided release coating or without a release coating based on your application.

Learn more about our 500 Series Hi-Shrink Tape.

Let’s Find the Right Electrical Heat Shrink Tape for Your Application

Dunstone has been proudly designing and manufacturing a full line of Hi-Shrink Tapes and Hi-Shrink Tubing for decades. Companies around the world rely on us for everyone from part consolidation to protection from wear and chemicals. Many of our products are customizable, allowing us to fine-tune their performance based on your application.

You can also request a complimentary sample of any in-stock heat shrink tape or tubing to test in your production environment. Simply get in touch with us, let our engineering team know what you’re looking to achieve, and we’ll get a sample sent out to you right away.

If you’re ready to take the next step, feel free to connect with us to learn more about our electrical heat shrink tape solutions.