Heat Shrink Release Tubing for the Composites Industry

There are many ways to manufacture a composite part. Two methods in particular that we have seen grow in popularity is the use of an inflatable bladder to layup on or the use of a SmartTool form. Both of these methods provide some distinct advantages but come with their own set of challenges as well. Dunstone has worked closely with manufacturers of both to develop an easy, effective and cost saving method of treating these tools with a release layer.

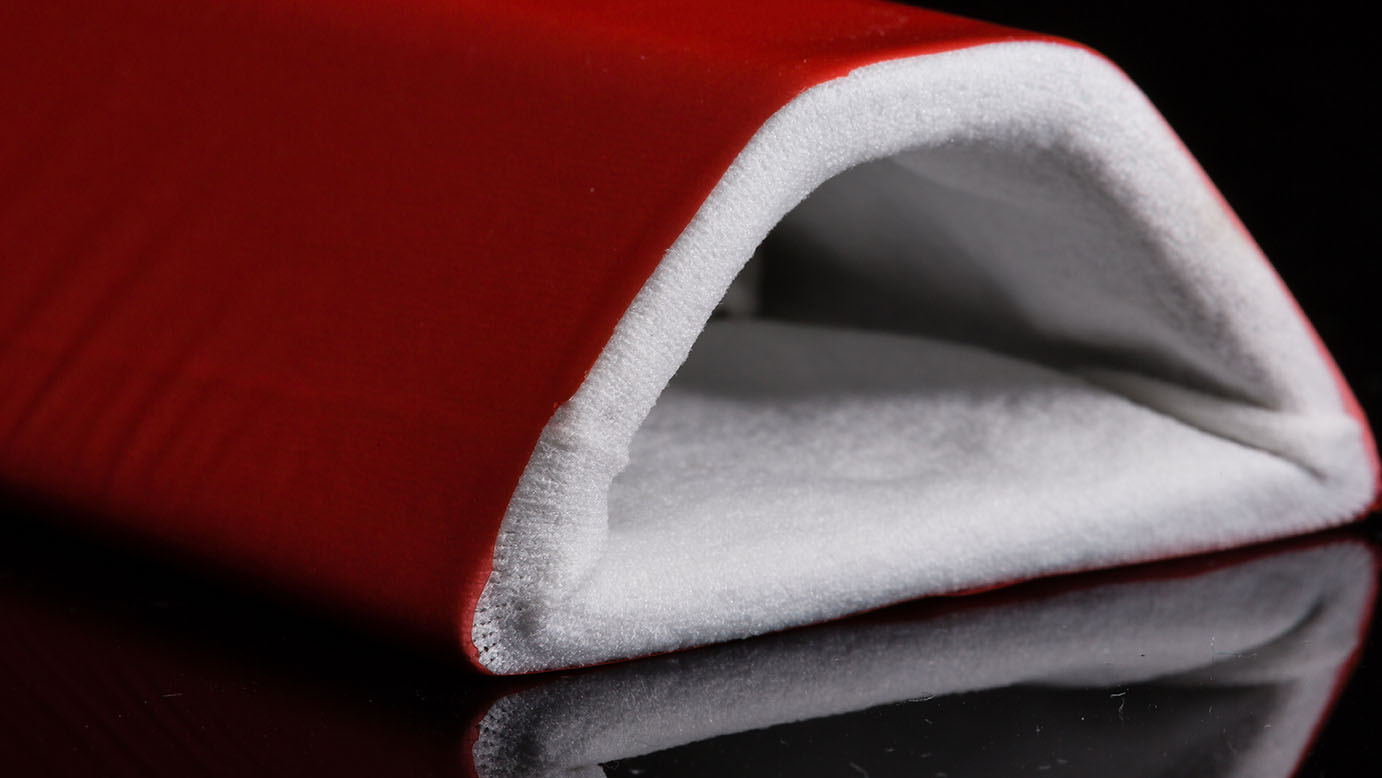

Our Hi-Shrink FEP tubing was originally designed to be used for treating omega shape stringer bladders and has since been used on a number of applications. The main benefit being the thin wall of the heat shrink FEP at .002″ providing a cost saving over traditional extruded FEP which generally measures at least .004″ thick. In addition the linear seam release film can be made in continuous length diameters up to 8″ currently. Current users have found the material very easy to apply and shrink down to a glassy finish free of wrinkles ensuring a high quality interior surface on their part.

Though the heat shrink release tubes generally come in FEP, they can also be made of ETFE or other release films at the customers request.

As opposed to standard taping of release film or using release tapes that stick to the bladder/tool, the ability to snuggly shrink a release tube down on the surface can save a substantial amount of prep time both before and after the cure cycle. In some instances the tubing can be used for more than one cycle. Dunstone is also actively working on near fit 3D sizing for the tubing allowing for the treatment of tapered components and more complicated geometries.

With the ability to precisely size components due to the method of linear seam manufacturing using flat film rather than an extruded tube, Dunstone can also manufacture long continuous lengths that will benefit any operation looking to automate the process of treating their part.

Contact us here if you have any questions or want a sample of our heat shrink FEP tubing