The Challenges of Compaction Films for Composite Tubes

The world of tape wrapping composite tubes isn’t new. There have been a variety of methodologies over the past half century to apply pressure to the outside of a mandrel wrapped composite tube. Most of these methodologies revolve around what we call compaction film. These are generally non-shrink or low-shrink polypropylene, nylon, cellophane etc. The theory is to wrap a part under the maximum tension the tape will permit at a steep pitch of usually just a few millimeters. There are, however, a few challenges with the age-old process for compaction tubing.

The First Challenge: Weak Compaction Force

The first and most significant is that all of the compaction force that part will ever see is during a dry, room temperature layup where the resin is at it’s highest viscosity and no heat is applied. The reality is that even at 40+ pounds of taping tension, once the part is introduced to the oven for cure, these tapes all relax at typical curing temperatures. This happens while the resin viscosity is dropping, which is not ideal for appropriate lamination and low porosity.

The Second Challenge: Material Usage and Time

The second challenge with traditional compaction films relates to yield and time consumption. With steep pitches and often several passes of over-wraps to generate in-spec parts, a large volume of tape is required and the process to remove tapes after cure can be time consuming. Many manufacturers of composite tubing rely on throughput to keep their process and products profitable.

How to Avoid These Challenges and Improve Your Composite Tubing

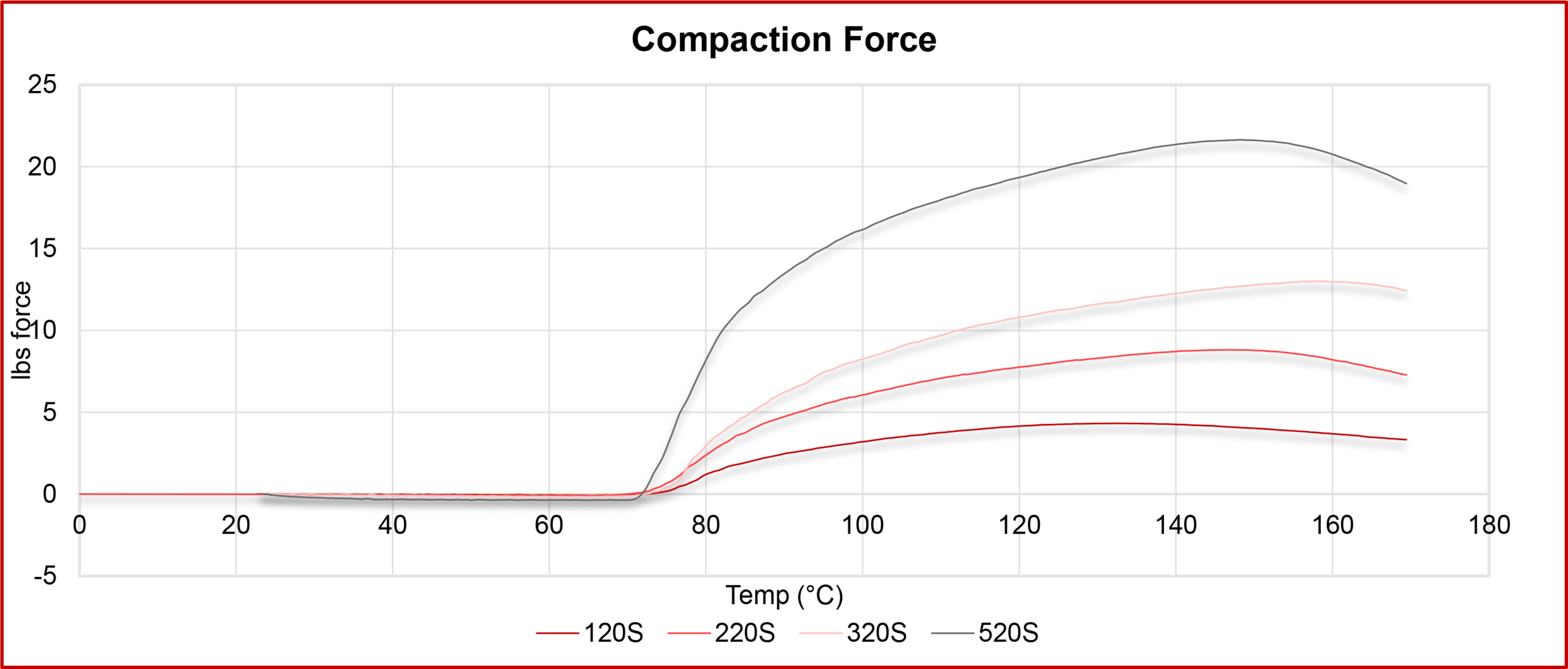

There are a few ways to deal with the challenges posed by compaction films for composite tubing. As you can see from the graph above, Dunstone’s Shrink Tape for composite tubing actually produces more force as temperatures elevate. The tapes are specifically designed to create the most force at the point where most common resin systems are at their lowest viscosity point. This ensures excellent consolidation and further reduces porosity by ensuring that every bit of material has resin forced through it at this critical stage in the curing cycle.

Learn Even More About Overcoming Compaction Challenges with H-Shrink Tape In Our eBook

Explore more of the benefits of upgrading from traditional compaction films to Dunstone’s Shrink Tape in our free downloadable eBook. Take a deep dive into the unique properties of Dunstone’s advanced Shrink Tape technology — and see for yourself how it outperforms traditional compaction films to improve the integrity of your composite tubing.

Learn even more about how Dunstone’s Shrink Tape can help you overcome the challenges of traditional compaction films in our free downloadable eBook.

Find New Time and Material Savings with Dunstone Heat Shrink Tape

As can be seen in the video below, the challenge of time and yield waste is addressed in two ways. First, our shrink tape for composite tubing is engineered to work best at 50% overlap (though more or less overlap can significantly affect the pressure/square inch applied to the underlying part). This means that with a 1.00” wide tape, all that is necessary is a 0.50” overlap, taped at moderate tensions of 5-8 lbs, to produce excellent results.

By comparison a 6-foot tube, 1.00” in diameter might consume ~246’ of 1.00” wide nylon at a 2mm pitch, single pass. The same part wrapped at 50% with Dunstone’s Hi-Shrink Tape would only consume 38’ of 1” wide tape. The reduction in applied material means a reduction in application time and less waste in landfills. Further reducing time and processing costs, our tapes come with an optional release coating that allows for easy removal of the tape post cure. You will find that our release coat works with most common resin systems.

Ready to experience the benefits of Dunston Shrink Tape for composite tubing?