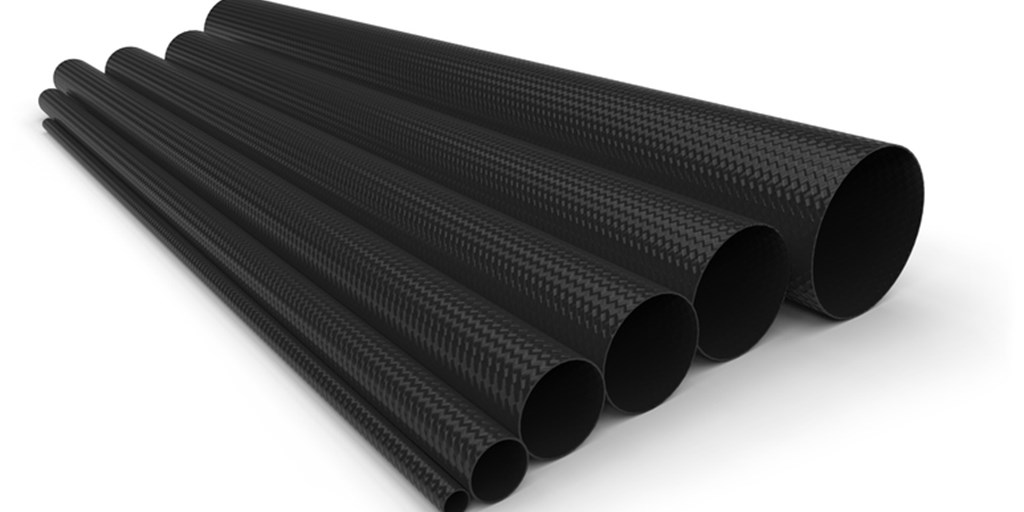

Numerous products today ranging from aircraft components and energy infrastructure equipment to electrical insulation materials and sporting goods use composites in their design.

These include carbon fiber, Kevlar, and even thermoplastics such as polyphenylene sulfide (PPS) and polyetheretherketone (PEEK). In many of these applications, extreme curing temperatures are needed to produce the performance qualities needed: high tensile strength, chemical resistance, weight-to-strength ratios, and other advantages related to the use of composites. A high-temperature heat shrink tape is the ideal solution for ensuring these properties are achieved.

The Hi-Shrink Tape is wrapped around the composite prior to being placed in an oven or being heated with a heat gun. This is done by hand or, in some applications, via a traverse winding mechanism that applies the tape laterally. As the temperature rises, the tape begins to shrink — applying force to the layers of composite material and resin between them. This force is necessary for a variety of reasons:

- Helping to ensure quality lamination and ply compaction

- Eliminating voids and preventing foreign object debris (FOD)

- Ensuring a consistent surface finish along the entire product

- Allowing for volatiles and gasses to escape when perforated

But when the application calls for higher-than-normal curing temperatures, standard compaction films and shrink tapes won’t be able to apply their tailored compression beyond a certain temperature — resulting in the tape and the curing process itself failing. In these instances, a high-temperature heat shrink tape is needed. Dunstone proudly offers two high-temperature heat shrink tapes to support these specific applications.

212HT: High-Temperature Stability & Flexibility

Our 212HT line of high-temperature heat shrink tape is a multi-layered ethylene tetrafluoroethylene (ETFE)-based film with a Nylon middle layer that is ideal for applications with temperatures up to 180ºC or 356ºF. At only 2 mils thick (0.002 in or 0.050mm), it is far thinner than competing solutions — meaning you use less overall material. It has a maximum shrink of 12%, applying 1.65 pounds of compressive force. In applications where components are being hand-taped, 212HT can be applied with up to 10 pounds of taping tension.

In addition to working well in high-temperature curing applications, 212HT is also extremely flexible. It features 300% elongation, allowing it to be used on a variety of parts with complex or uneven surfaces. As a naturally releasing fluoropolymer film, 212HT does not require a coating in order to provide outstanding release characteristics and won’t leave any trace residue on parts. It is available on 1.5” or 3” internal diameter (ID) cores and in standard widths from 0.5” up to 2.5” to ensure you have the right coverage for your application.

Download the 212HT data sheet | Request a free sample

208X: High-Temperature Mechanics & Insulation

Our most popular high-temperature heat shrink tape is our 208X series — the highest-temperature Hi-Shrink Tape available that’s capable of providing compressive force in curing cycles with temperatures up to 400ºC or 752ºF. It is made of a modified polyimide and begins to shrink at approximately 70°C (158ºF), reaching maximum compressive strength at 350ºC (662ºF). 208X is often used in electrical coil consolidation to provide a smooth surface finish but is also used for dielectric insulation alongside its mechanical compressive properties.

This high-temperature heat shrink tape features a maximum shrink of 14%. Shrinking begins at 70ºC, reaching 8% shrink at 225ºC and the full 14% near 400ºC. In mechanical usage instances, the tape can be used up to the full 400ºC temperature. In electrical applications, users should limit temperatures to 220ºC (428ºF). As part of the greater 200 Series of Hi-Shrink Tapes, 208X is also only 2 mils thick, is non-release coated but can serve as a release layer, and can withstand far greater taping tension than the 212 HT line — up to 50 lbs. This particular tape is highly customizable as well, allowing our team to create a solution specific to your needs.

Download the 208X data sheet | Request a free sample

Get the Right Shrink Solution for Your Goals

Dunstone has been proudly engineering and manufacturing a full line of Hi-Shrink Tapes and Hi-Shrink Tubing solutions for years. Serving organizations worldwide, our tapes have helped numerous companies produce high-quality, top-performing products in markets such as aerospace, automotive, industrial products, oil and gas, consumer goods, energy, and more. We also specialize in completely customized solutions to support your unique projects. Whether you’re looking for a better-performing solution for your compaction needs or are exploring options for a new product line or application, our team is ready to help.

Connect with us today to learn more about our high-temperature heat shrink tape