Change Necessitates Change

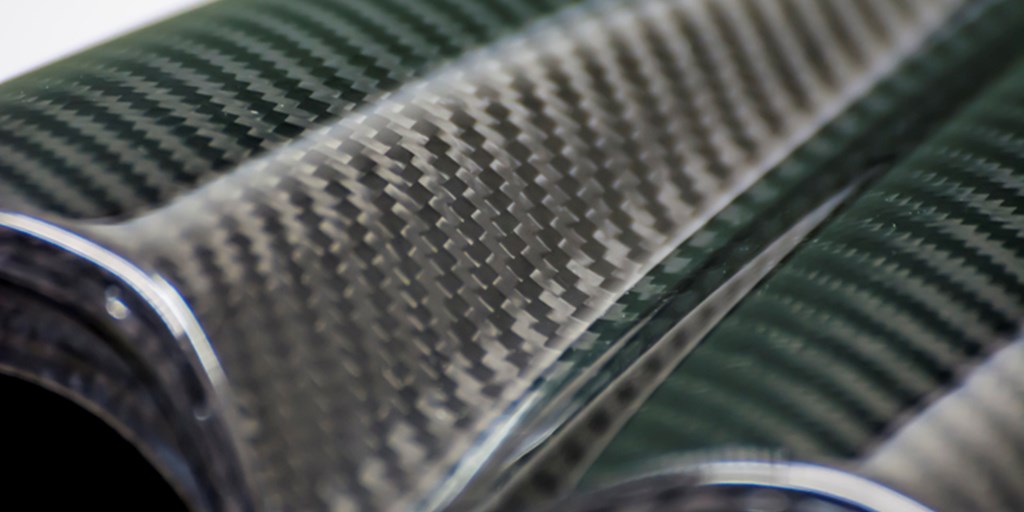

The current economic environment has led to a variety of supply chain and production changes for multiple industries. This is no different for manufacturers of composite products that serve critical functions in multiple downstream markets such as energy, oil and gas, automotive, aerospace, sporting goods, and more. One key challenge for composite manufacturers has been finding the right heat shrink tape to fit their new compaction requirements.

This particular material challenge comes hot on the heels of composite manufacturers struggling to find suitable alternatives solutions to already solved problems. Additionally, manufacturers that have implemented new resin systems are finding them incompatible with their previous compaction solution. This is if such resin systems are even available, as material shortages — including composite fibers themselves — have impacted manufacturers worldwide.

As a result of all of this change, companies are beginning to explore new solutions for maintaining and improving performance during the curing cycle. Whether your current shrink tape solution is no longer available, it’s no longer compatible with a new resin system you’re working with, or you’re experiencing quality issues as a result of change (e.g. delamination, porosity, inconsistent surface finish, or voids) or maybe you have other concerns with your existing resin system such as labor intensive compaction solutions. It may be time to explore your options for a resin heat shrink tape alternative.

Why You Might Be Experiencing Issues

Voids and Porosity

A common cause of these physical problems is the presence of gas and other volatiles that are unable to escape during curing. Additionally, many non-shrink films and tapes don’t provide the tailored compaction needed as curing temperatures rise. Thus, gasses and volatiles aren’t compressed, forced through the matrix, and allowed to out-gas (escape).

Solutions:

- The first step is using a Hi-shrink tape that applies compressive force as the temperature rises. Cellophane, nylon, and other materials require tight wrapping tension up front in order to apply compression, but they can weaken during cure. At Dunstone, our Hi-Shrink Tapes are custom-tailored to apply greater force as the temperature increases — right as resins begin to drop in viscosity. This ensures that consistent compression is applied to the part and prevents voids from forming.

- Another key solution is using perforated tape. Often, people mistakenly believe perforations are for allowing resin to escape, but the reality is that material can escape between the layers of tape. The perforations actually allow gasses to escape as more and more compression is applied. Combined with a proper heat shrink tape, perforations ensure that your composite parts are free of voids and porosity.

Delamination and Surface Finish Problems

Delamination and inconsistent surface finishes typically result from incorrect application of a heat shrink tape or insufficient compaction. Improperly wound tape that doesn’t have the right (and consistent) amount of overlap and surface tension won’t apply the same amount of compressive force during cure. The same will affect the resulting surface finish.

Solutions

- Learning how to properly wrap Hi-Shrink Tape will go a long way in ensuring each application is consistent and achieves the desired results. While some experimentation is needed (particularly for newer products, resins, and fibers) to find the right tension, overlap, etc., experimenting until you find the right results will ensure the best possible outcome. Ask us about the variables affecting compressive force on a part.

- Similar to issues with voids and porosity, it’s critical that you use a resin shrink tape that will apply consistent compressive force. A variety of Hi-Shrink Tapes are available based on your application and the amount of force needed. Discussing your application with an engineer will help you find the right option.

Even If You’re Not Having Issues, It’s Likely That Improvements are Still Possible

Whether you’re experiencing the issues above with your resin heat shrink tape or are moving forward in your production without issue, now is always a good time to ensure you have the best possible shrink tape solution available. Often, companies are able to reduce costs with thinner or even less compaction tapes while still benefiting from the same or greater amount of compressive force. It all depends on the material and who you’re working with.

At Dunstone, we work closely with each client to understand their unique application, their intended performance outcomes, and their supply chain goals. In virtually all cases, we’re able to recommend a Hi-shrink tape that provides more consistent compaction while also reducing costs. Many of our tapes can be traverse-wound as well, enabling greater automation during a time when skilled labor is difficult to find.

The best first step is connecting with our sales and engineering team to discuss your application. If we have a shrink tape solution for you, we can provide a sample so you can safely test it in your production environment to see if it melds well with your process and materials. We are also able to customize our tapes for more specific performance needs.

Get in touch with us today to learn more and to request a sample.